Revolutionizing Encapsulation with Microfluidic Reactor Technology

Technology

Microfluidic reactor technology represents a significant advancement in the encapsulation of active molecules. Unlike traditional methods, which often suffer from particle size control and uniformity limitations, microfluidics enables precise manipulation of fluids at the microscale. This results in consistently sized nanoparticles and liposomes, which are crucial for the stability and bioavailability of encapsulated compounds. At UFChipTech, our microfluidic reactors ensure that each batch of nanoencapsulation products meets strict quality criteria, providing our clients with reliable and effective solutions.

Sustainable and Scalable Solutions

Sustainability is a core value at UFChipTech. Our microfluidic reactor technology is designed to be both energy-efficient and scalable, making it suitable for large-scale production without compromising on quality. The precision of microfluidics reduces waste and ensures that resources are used optimally, aligning with our commitment to environmental responsibility. Whether you are looking to develop a new pharmaceutical product or a cutting-edge cosmeceutical, our technology provides a sustainable and scalable solution that meets your needs.

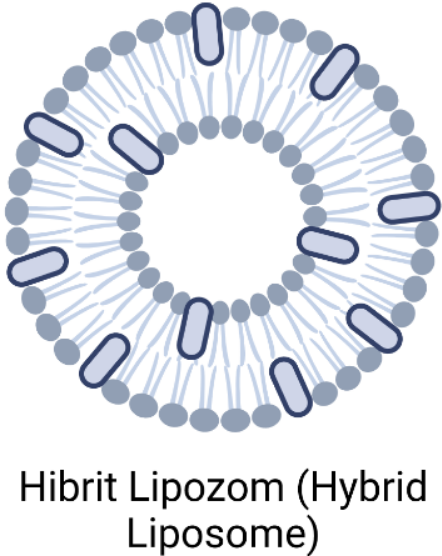

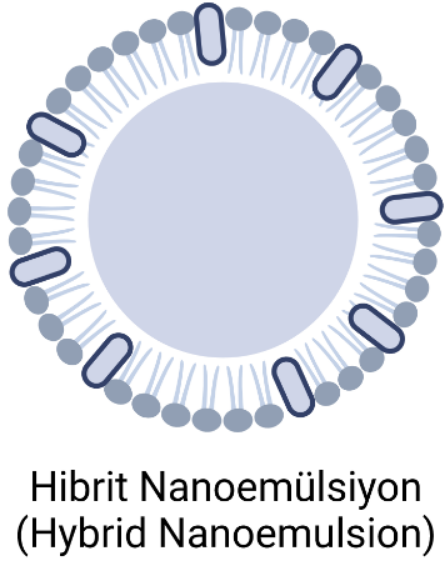

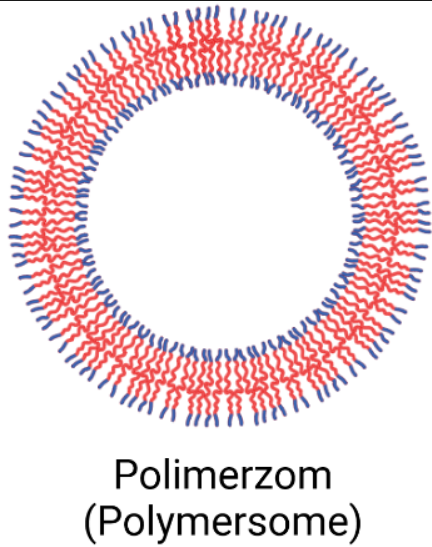

WHAT IS HIBRID NANOLAYERED TECHNOLOGY

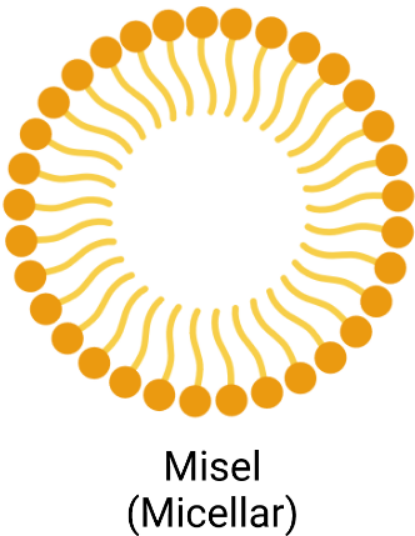

Particle Nomenculature by SizeLipid micellar: Micelles formed by self-assembly of amphiphilic lipid molecules in aqueous solution, with a hydrophobic core that can encapsulate drugs.

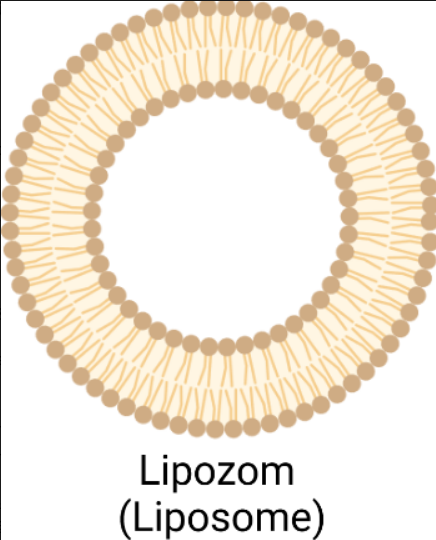

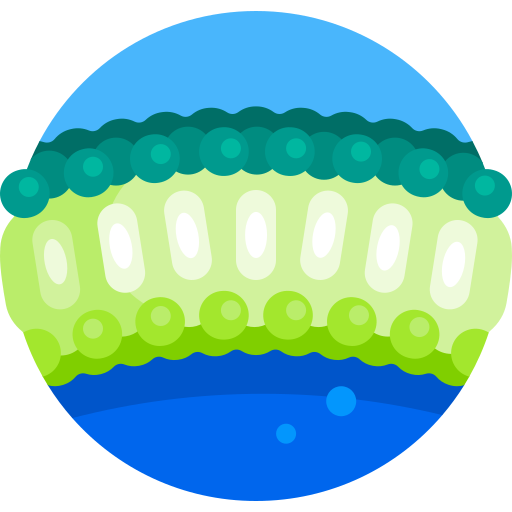

Nanoliposome: Liposomes with nanoscale dimensions, typically 10-100 nm, which can improve drug delivery and pharmacokinetics.

Nanoemulsion: Emulsions with nanometer-sized droplets, often stabilized by surfactants, that can enhance solubility and bioavailability of drugs.

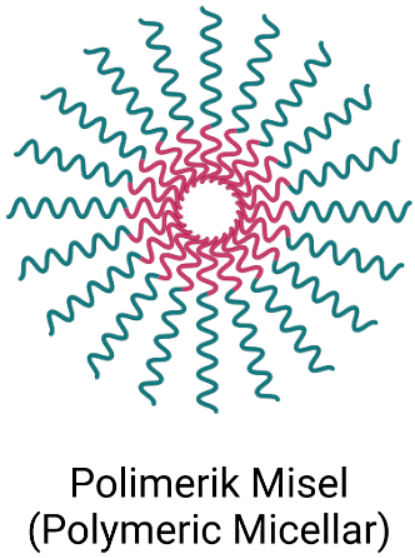

Dendrimer: Highly branched, tree-like polymer molecules with a core and multiple generations of branching, used to improve drug solubility and targeting.

Polymer micelle: Self-assembled nanostructures formed from amphiphilic block copolymers, with a hydrophobic core that can encapsulate drugs.

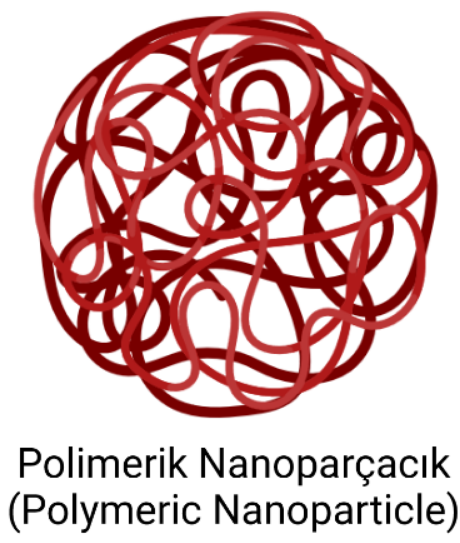

Polymer nanoparticle: Solid polymeric nanoparticles that can be used to deliver drugs, proteins, genes, and other payloads.

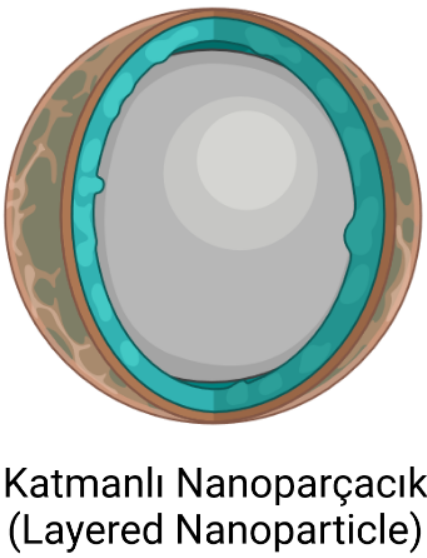

Lipid nanoparticle: Lipid-based nanocarriers that encapsulate and deliver nucleic acids like mRNA, siRNA, and DNA. They typically contain ionizable cationic lipids, cholesterol, phospholipids, and PEG-lipids that form a protective shell around the nucleic acid cargo. Lipid nanoparticles can efficiently deliver nucleic acids into cells and have enabled the clinical translation of many nucleic acid therapeutics.

Nanogel: A hydrogel with nanoscale dimensions, typically 10-100 nm, that can be used to encapsulate and deliver various payloads like RNA nanocarriers. The hydrogel network can help improve the loading, stability, and transfection efficiency of the encapsulated RNA nanocarriers compared to naked RNA delivery. Nanogels can be formed from materials like fibrin, collagen, or hyaluronic acid.

Visual Description of Some Particle Types

UFCHIP MICROFLUIDIC REACTOR TECHNOLOGY

Liposome Generation Techniques

Bulk Methods: Bulk methods involve the swelling of initially dried preorganized lipid films (rehydration methods) or the use of cosolvents, coamphiphiles, or specific ionic species to influence lipid aggregation. These methods can produce liposomes of various sizes and are commonly used in industrial settings.

Thin-Film Hydration: This method involves hydrating a dried thin film of phospholipid to form liposomes.

Membrane Contactors: This method uses a membrane contactor to facilitate the formation of liposomes. It is particularly useful for encapsulating bioactive compounds and has been used to prepare liposomes with high encapsulation efficiency.

Microengineered Membranes: This method involves the use of microengineered membranes to investigate process parameters and apply them to the encapsulation of actives.

Supercritical CO2: This method uses supercritical CO2 to extract lipids from a mixture, resulting in the formation of liposomes. It is a sustainable technology for liposome preparation and can be used to produce liposomes with specific properties.

Electroformation: This method uses electrical fields to form liposomes. It is particularly useful for producing giant unilamellar vesicles and has been used to encapsulate various substances.

Microfluidic Technique for Nanoparticle Synthesis

Microfluidics is used to synthesize nanoparticles, including liposomes, in a controlled and reproducible manner. It involves the use of microfluidic devices to handle fluids in geometrically constrained compartments, reducing the use of materials and reagents. This method is particularly useful for the production of uniform nanoparticles with precise size and size distribution.

Hydrodynamic Focusing: This method uses hydrodynamic focusing to produce monodisperse, cell-sized unilamellar liposomes with high encapsulation efficiency.

Herringbone Channels: Microfluidic channels with a herringbone-patterned groove design that can enhance mixing and improve the synthesis of nanoparticles. The herringbone grooves create vortices and chaotic advection that promote efficient mixing of the fluids.

Angled Immediate Mixing Channels: Channels with a special geometrical design called angled channels provide an important characteristic to mix two or multiple liquids immediately. So lipids or some other polymers not dissolving in aqueous solutionsencapsulate actives in aqueous solutions. This is the most novel microreactor channel design with the highes quality possible nanoparticle synthesis together with highest possible throughput.

FEATURES

Novel microfluidic reactor technology for hibrid encapsulation of active molecules

Patented unique and customizable process of high throughput process

High quality particle synthesis with size mono dispersity

Multiple hibrid layers of lipid and polymeric materials for better bioavailability

ADVANTAGES

More bioavailable with enhanced permeation through gut and skin

Higher thermal and pH stability

Smaller size of particles and higher size mono dispersity

Liquid and solid dry formats available

Maximum possible benefit

THE SCIENTIFIC RESULTS

Electron Microscopy Image

Size Distribution Monodispersity

Zeta Potential Unique

In Vitro Permeability Study

In Vivo Pharmacokinetics / Pharmacodynamics